PAT Testing Frequency

Explanation of PAT Testing Frequency Chart

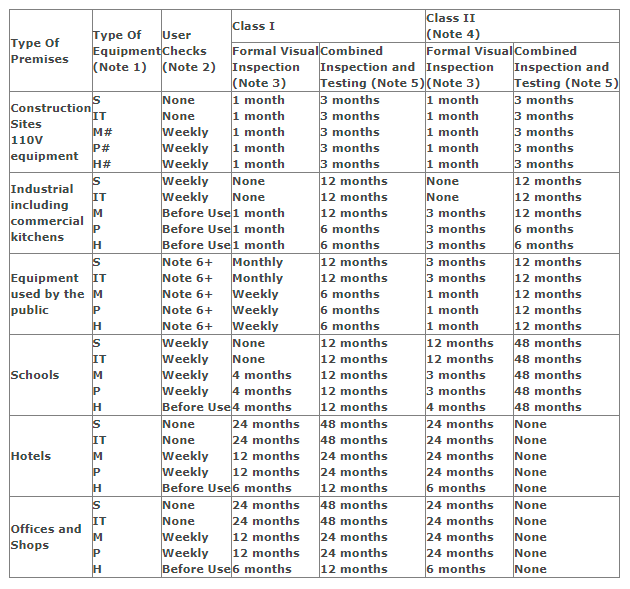

A PAT (Portable Appliance Testing) testing frequency chart is a tool used to determine how often electrical appliances should be inspected and tested for safety. It guides the recommended intervals for conducting these tests based on factors such as the type of equipment, its location, and the environment in which it is used. Following the guidelines on the chart helps ensure that appliances remain safe to use and reduces the risk of electric shock or other electrical hazards.

It is important to note that the table provided is for guidance purposes only. Each premise should be assessed individually based on the specific conditions of the situation to evaluate the hazard and minimise the risk of electric shock.

Frequency of Portable Appliance Testing.

The underlying principle for frequency of pat testing is that the duty holder, i.e. the person with the equipment within his control with the advice of the competent test person when necessary, must assess the need for portable appliance testing the equipment against the following:

1. Type of equipment: portable, handheld or transportable

2. Style of use: continuous, infrequent, rough equipment age.

4. If regularly moved or transported, by what means?

5. Type and competence of personnel using the equipment.

6. Environment of usage outdoors, construction sites, hazardous atmospheres, etc.

7. Results of previous pat tests.

8. Manufacturer’s recommendations.

9. Effect of any modifications or repairs to the portable appliances.

(Note 1) Equipment Type Key:

S: Stationary Equipment

IT: Information Technology Equipment

M: Moveable Equipment

P: Portable Equipment

H: Handheld Equipment

(Other Notes)

2. User checks are not recorded unless a fault is found

3. The formal visual inspection may form part of the combined inspection and tests when they coincide and must be recorded.

4. If the class of equipment is not known, it must be tested as Class I

5. The results of combined inspections and tests are recorded

6. For some equipment such as children’s rides a daily check may be necessary

7. By supervisor/teacher/member of staff

8. 110V earthed centre tapped supply 230V portable or handheld equipment must be supplied via a 30 mA RCD and the intervals between inspections and tests reduced

The information on suggested initial frequencies for pat testing as above is more detailed and specific than HSE Guidance, but is not considered inconsistent with the guide.